Welcome to USC Technologies

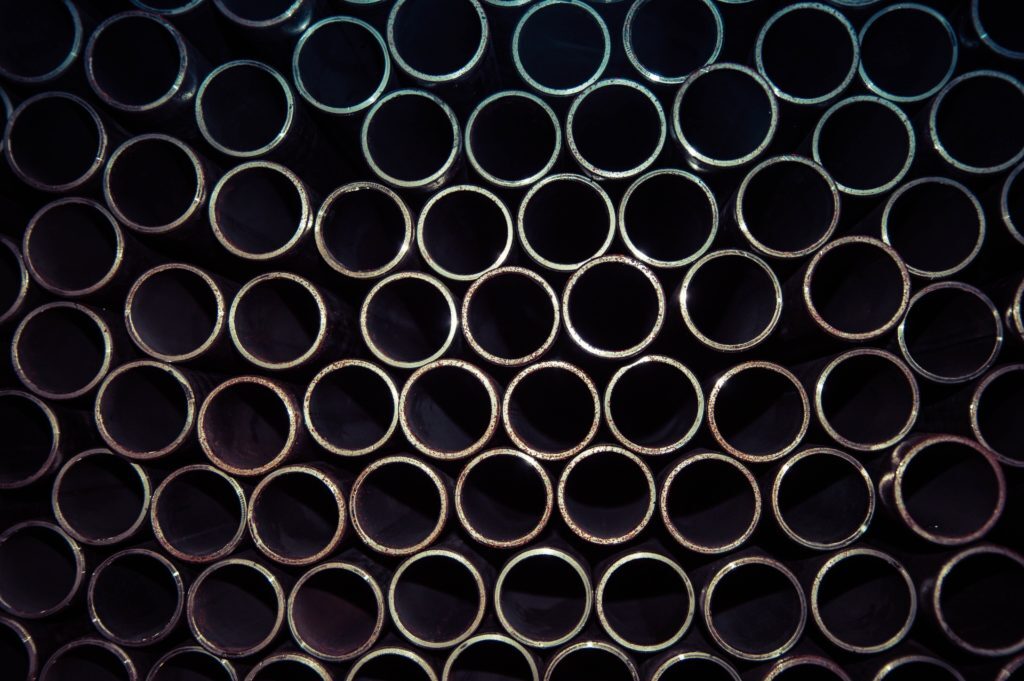

USC Technologies has developed and made commercially available a breakthrough family of economical, electrolytic coatings that are direct replacements for hard chrome, electroless nickel, thermal spray coating, HVOF, and nitriding.